SUMOBOTS

Project Overview

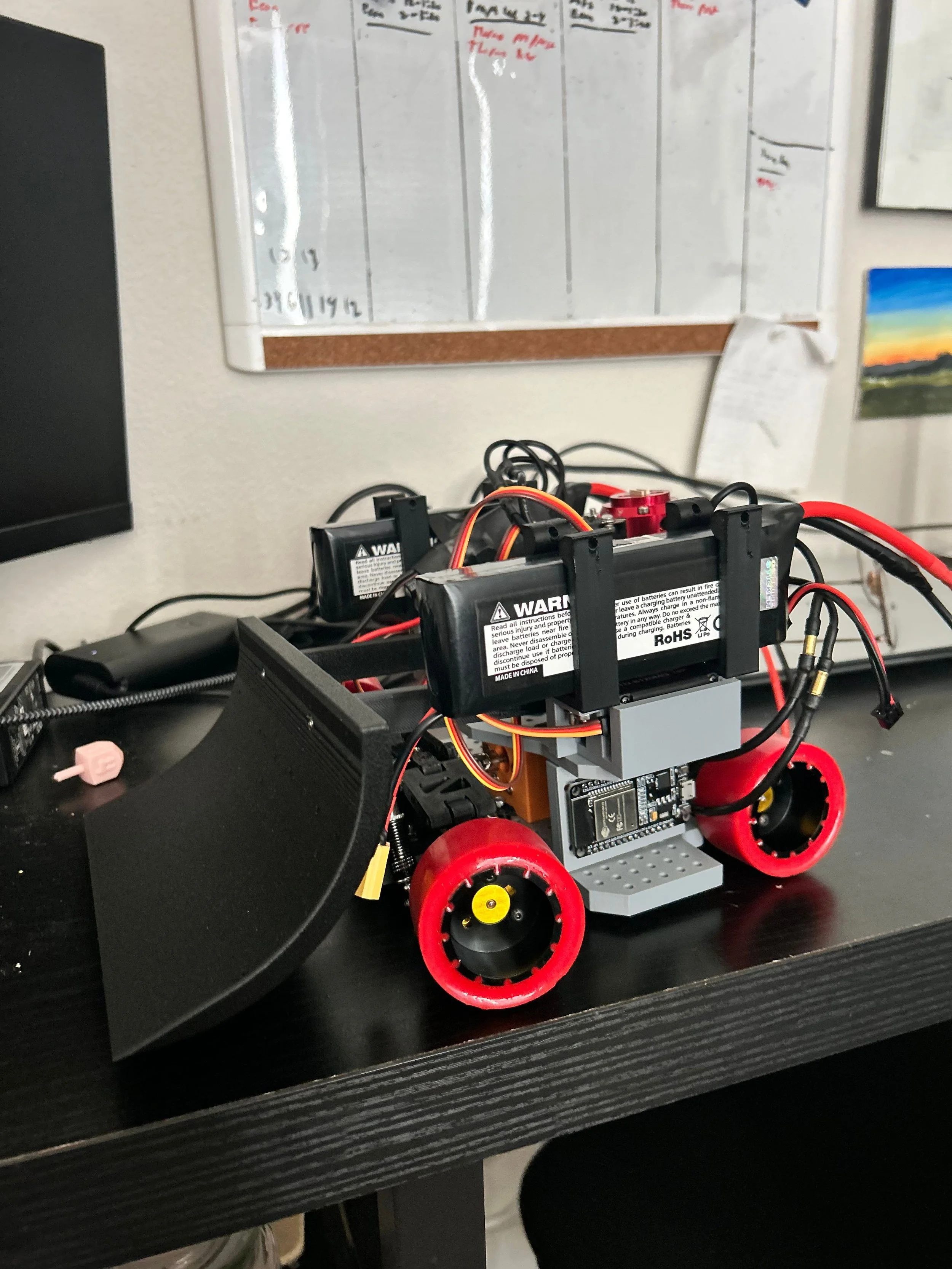

For my Mechanical Engineering capstone project, I participated in a SumoBot competition where teams designed and built remotely controlled robots to compete in a circular arena. The objective was to push opposing robots out of the arena using offensive and defensive strategies. Our design complied with the rules of the Sumobot Society, Capstone Event guidelines, and specifications from Dr. Oman.

Key Specifications

Maximum size: 20 × 20 cm

Maximum weight: 3 kg (6.6 lbs)

Budget: ≤ $500 (unless sponsored)

Body design must be geometrically unique (box-style frames prohibited)

Role: Lead Designer & Development Engineer

Directed the design workflow and provided technical feedback to teammates

Selected and tested durable 3D printing materials for performance reliability

Conducted mechanical simulations in SolidWorks (impact, bending, stress)

Process

Designed and simulated components in SolidWorks and Fusion 360

Prototyped with PLA; fabricated final components in PHAT-CF (carbon fiber-reinforced)

Used Bambu Lab and Anycubic 3D printers for manufacturing

Results

Built one of the most impact-resistant robots in the competition

Survived direct collisions with BattleBots

Demonstrated that simple, robust designs often outperform complex alternatives

Skills Utilized:

CAD (Solidworks, Fusion 360)

Soldering

3d Printing

Arduino/C++

General tool Hardware

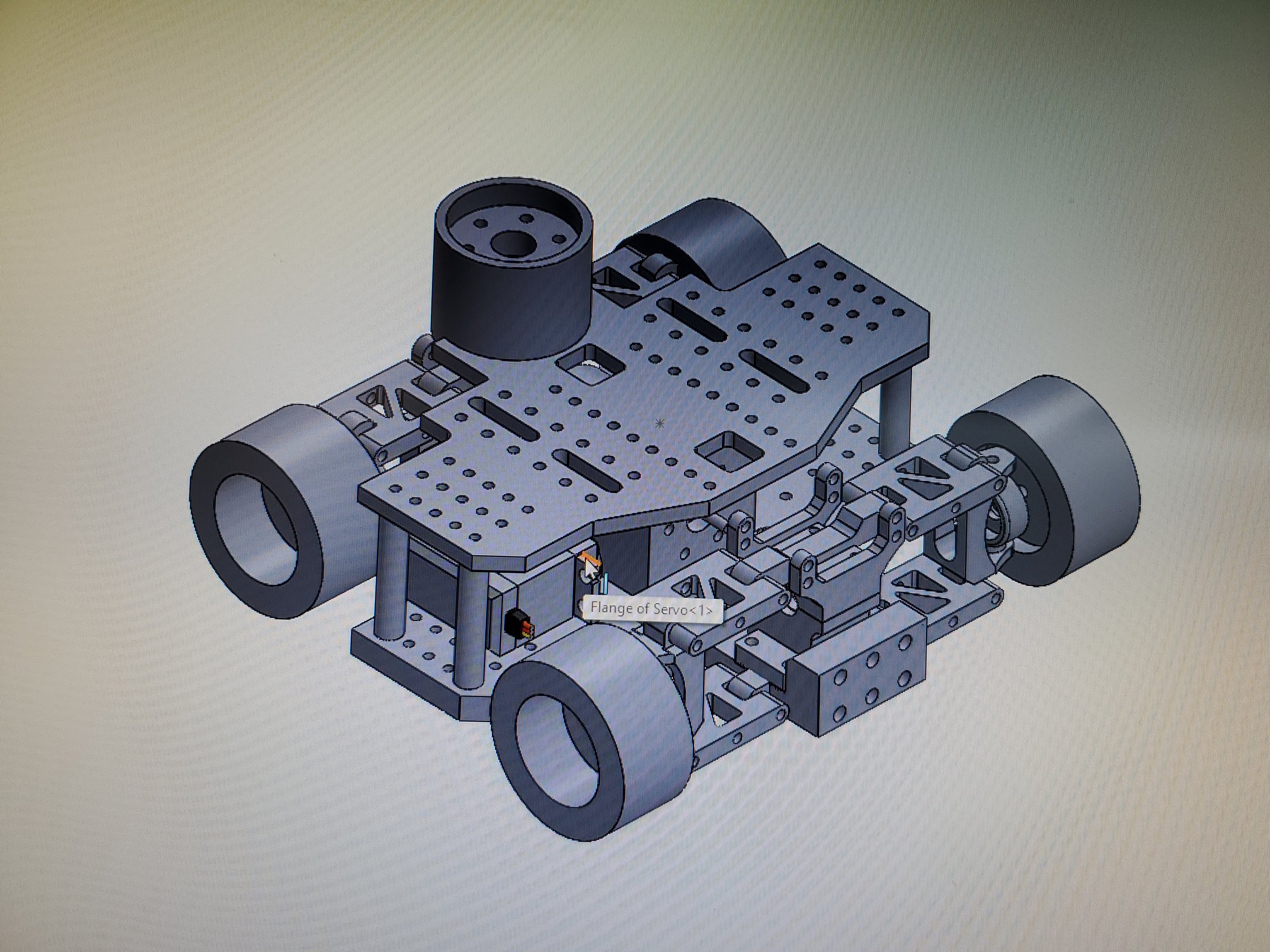

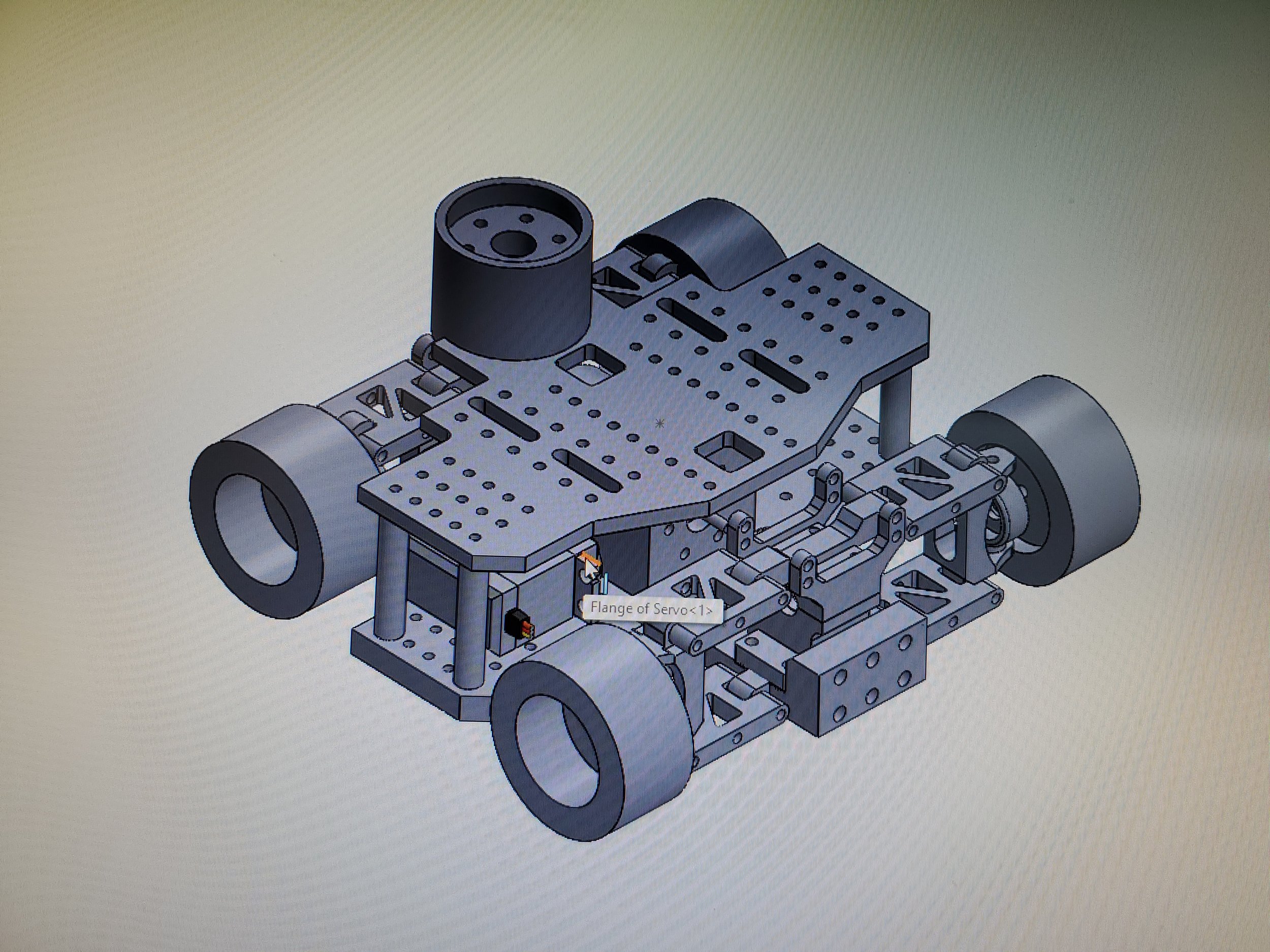

Version 1 of our sumobot

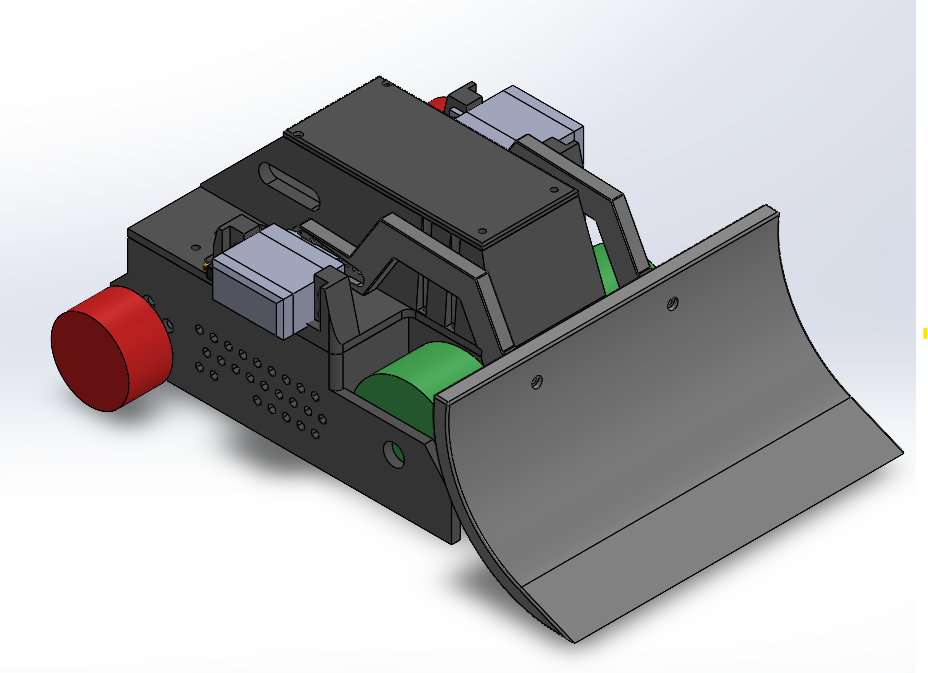

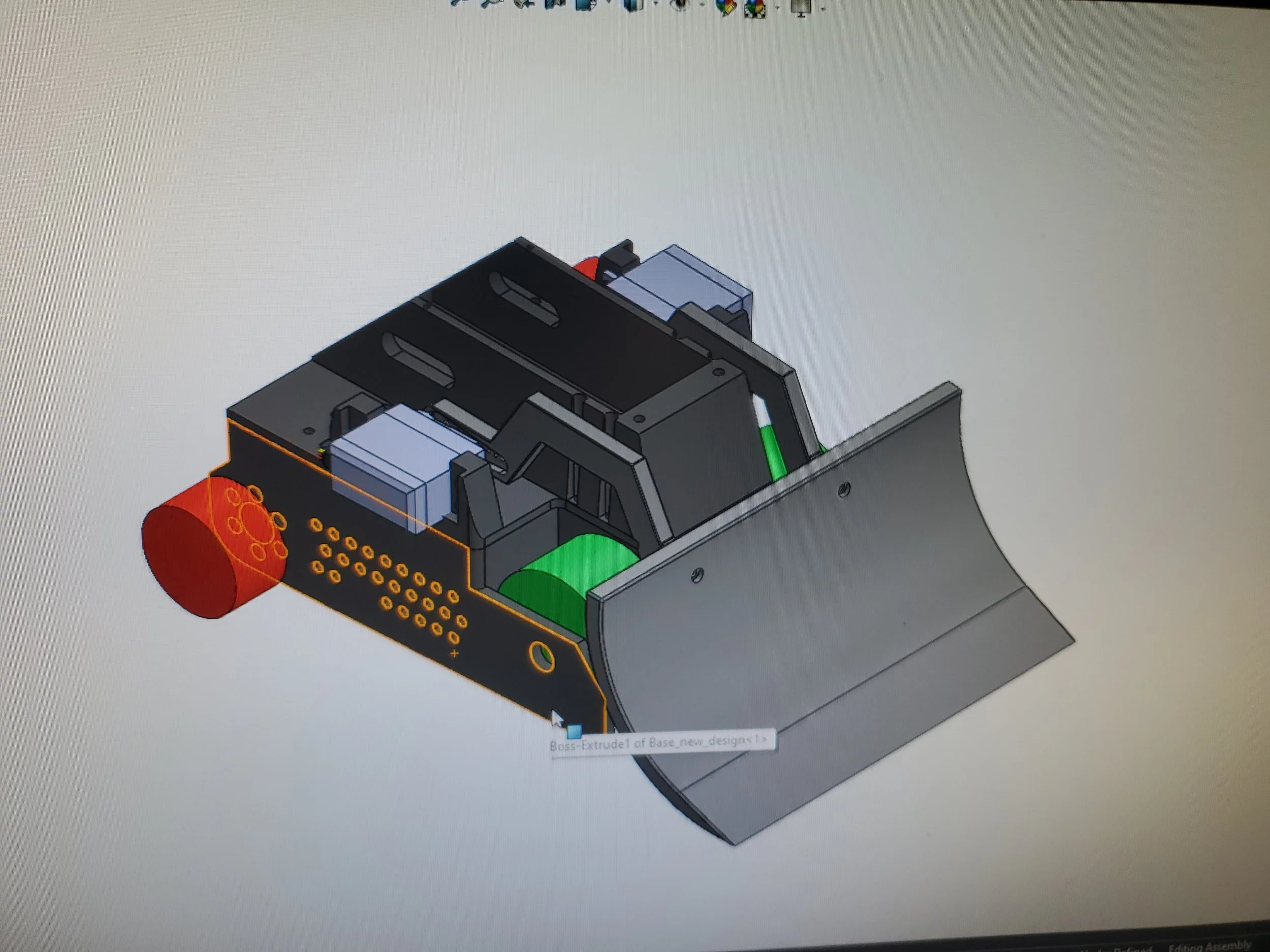

Final Design [Version 4]

Fully built robot