about me

Hi, my name is Miguel A. Garcia, and I’m a recent Mechanical Engineering graduate from Oregon State University with a passion for fabrication, design, and mechanical systems. From building robots to machining custom parts, I enjoy the process of turning ideas into tangible solutions.

My strengths lie in both digital and hands-on engineering. I am experienced in CAD modeling (SolidWorks, Fusion 360, AutoCAD) and creating precise engineering drawings using GD&T standards. On the fabrication side, I’ve gained practical skills in soldering, sheet metal bending, machining, and 3D printing — blending theory with real-world application.

Beyond the classroom, I’ve always been a tinkerer at heart. Many of my skills, including 3D modeling and programming, were self-taught through curiosity and personal projects. This drive to learn fuels my creativity and gives me the confidence to experiment and iterate until I find solutions that work.

All in all, I hope to design and develop critical mechanical systems or machines that improve people’s daily lives, regardless of the industry they serve. For me, engineering isn’t just about solving problems — it’s about creating tools that make the world a little more efficient, accessible, and human-centered.

WOrk Experience

PCC Structural [SSBO] - Facilities Engineer Intern

[March 2024 - September 2024]My second internship at PCC Structurals SSBO allowed me to step into the role of a Facility Engineer, where I led diverse projects aimed at optimizing machine performance, enhancing safety, and improving ergonomic conditions. Each project challenged me to coordinate across departments and collaborate with external partners to deliver practical, production-friendly solutions—ensuring minimal disruption to manufacturing operations.

Skills utilized

CAD (Solidworks, AutoCAD)

Engineering Drawings [GD&T Y14.5-2018/ PCC Standards]

Time Management

Professional Reports and Presentations were delivered

Boeing Inc- Manufacturing Engineer Intern

[March 2023 - September 2023]My first internship at Boeing introduced me to the fast-paced world of aerospace manufacturing, where I worked as a Manufacturing Engineering Intern on the Horizontal Build Line team. Tasked with building the core wing structure, I investigated production issues and championed corrective actions aligned with lean principles. Through this process, I developed mechanical and procedural solutions that meaningfully reduced nonconformance and improved both quality and efficiency.

I also had the opportunity to collaborate with the tooling engineer team, where I helped design ergonomic tools in CATIA V5 and brought them to life using 3D printing—an experience that introduced me to the professional world of engineering.

Skills used:

CAD (CATIA V5)

Engineering Drawings [GD&T Y14.5-2018/Boeing Standards]

Scientific Method

Time management

Professional Reports and Presentations were delivered

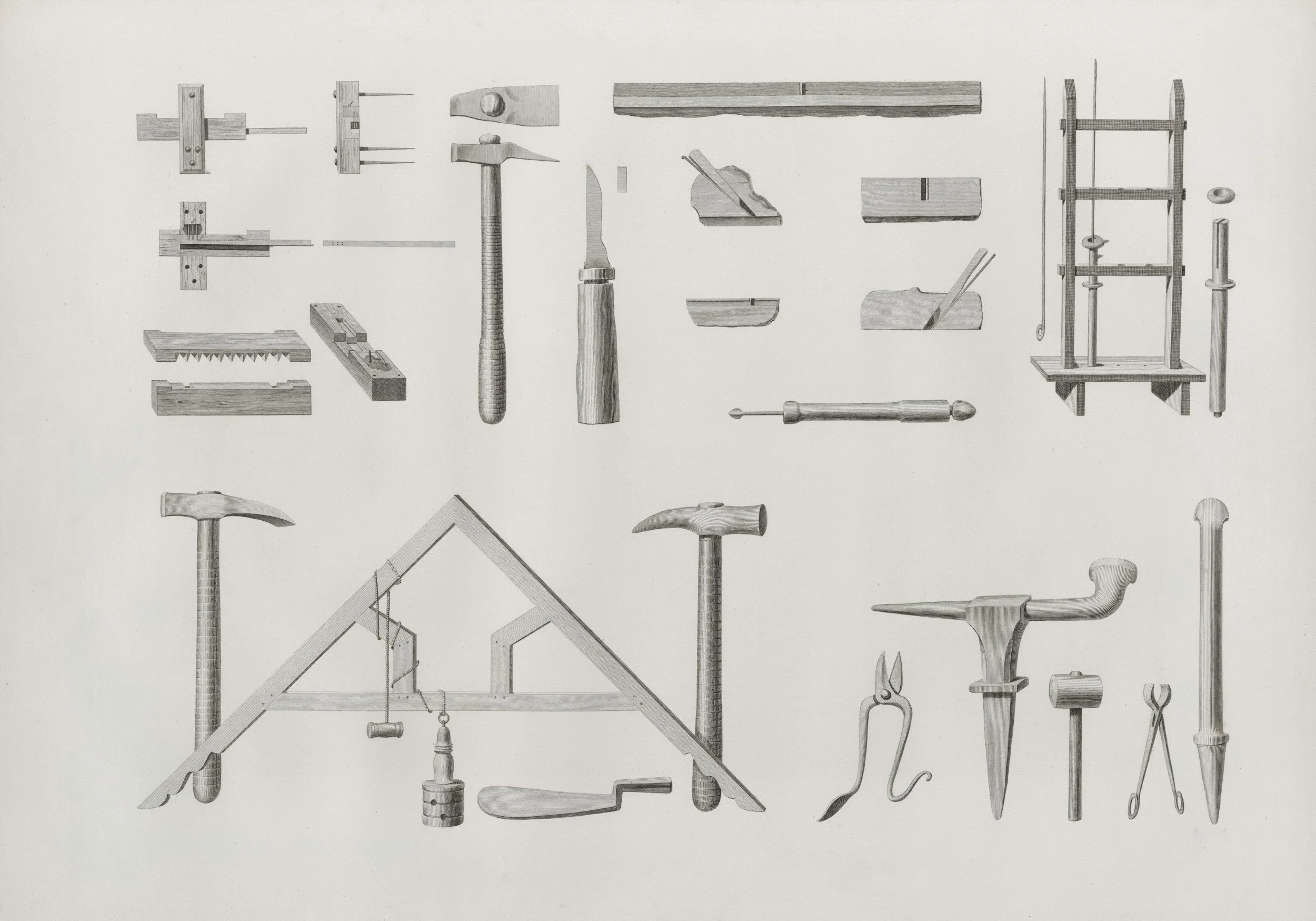

General Laborer (Landscaping/ CarpentrY)

Watsonville, CA

Assisted in landscaping and carpentry projects, applying mechanical aptitude and attention to detail in construction and maintenance tasks.

Operated power tools and light machinery, including tractors and lawnmowers.

Installed small-scale structural and irrigation systems, such as a retaining wall and a plant watering system.

Planned and organized work schedules to meet project deadlines and maintain productivity.

Computer Technician

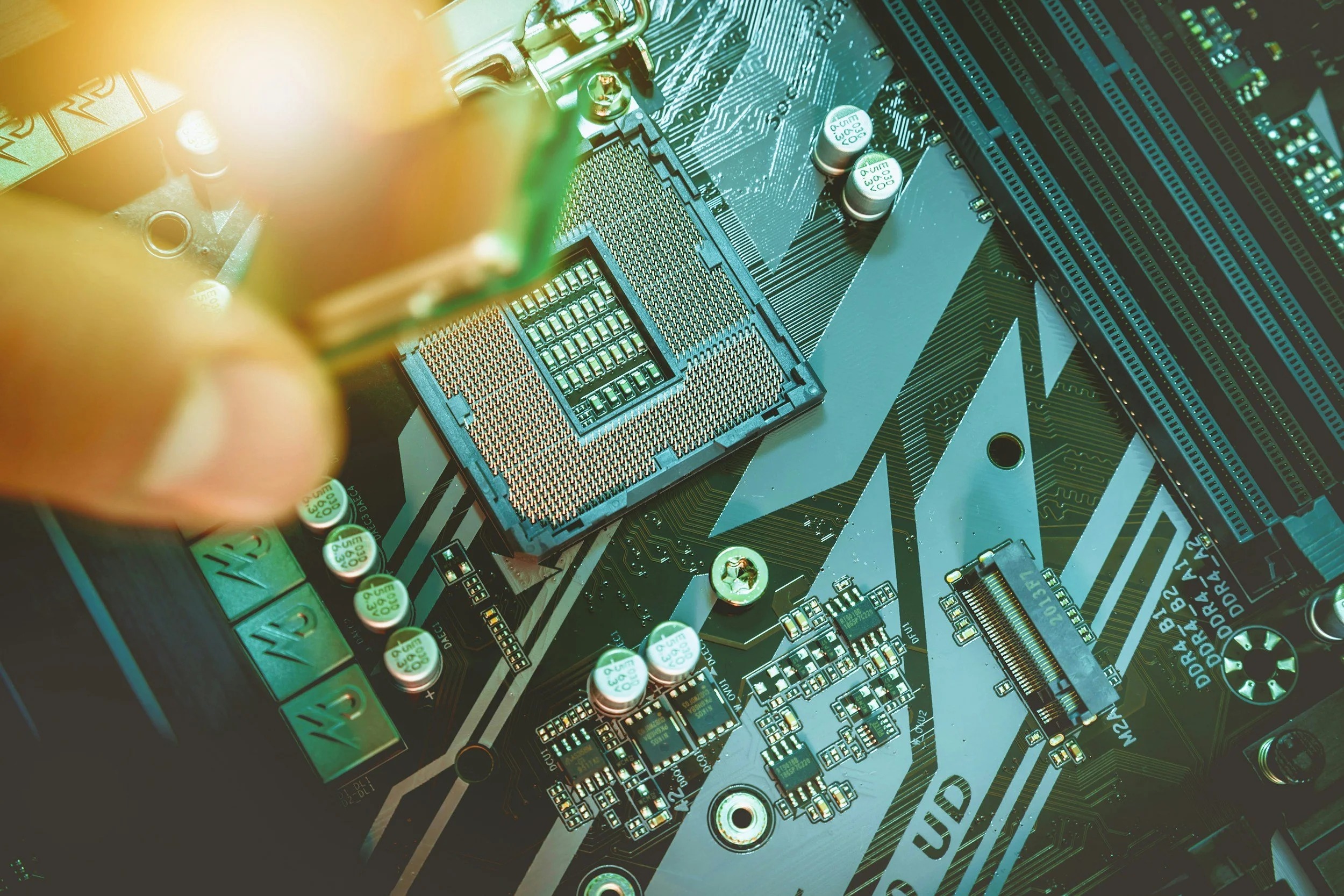

Digital Nest / Ceiba College Prep Watsonville, CA

Collaborated with staff to maintain and organize the school’s and non-profit’s technological infrastructure, ensuring reliability and efficiency across all equipment

Communicated effectively with staff and members to identify system issues and propose practical, timely solutions.

Diagnosed and repaired computer hardware components, including displays, keyboards, and power systems, applying problem-solving and hands-on repair skills.

Performed precision soldering and component replacement on printed circuit boards, reinforcing attention to detail and technical accuracy.

Managed the computer inventory system by tracking, updating, and checking out equipment to users, supporting streamlined operations and accountability.

Contact ME

Interested in working together? Fill out some info and we will be in touch shortly. We can’t wait to hear from you!